Wetsuit stitching

A wetsuit's function is to keep you warm in the water, and there are a number of different methods used to ensure it's up to the task. The process of making a wetsuit involves stitching together different shaped pieces of neoprene.

As you might expect, there's a little more involved in wetsuit construction than just a needle and thread, just in case you though you were ready to knock one up for the weekend session. It's not just a great fit that ensures a wetsuit is nice and warm. If you're a lightweight summer surfer, this information is probably not that interesting, you should head straight for the board shorts page.

Seams

A well fitting wetsuit is essential for warmth, and the fit is achieved by the use of separate, tailored panels. These panels are joined to each other by stitching along seams. The seams are less flexible than the sheet neoprene. In a good quality wetsuit, seams are kept away from areas were high flexibility is important. Seams should not run along the shoulders or under arms, where they could intrude on paddling areas. In a poor quality wetsuit, water will flood through the seams, quickly turning your nether regions blue!

More Seams

- a better fitting wetsuit

- can be glued to prevent water coming in

- reduces flexibility

- Increases the likelihood of chafing caused by a seam,

Less Seams

- Less chance of water entering the suit

- Poorer fit, although this is becoming less and less a problem with new neoprene technology

Stitching

There are three types of stitching used in wetsuit construction. As you might guess, stitching involves making holes in neoprene and passing a thread through. These holes can let water though the waterproof neoprene, so the type of stitching is important when considering how warm a wetsuit will be.

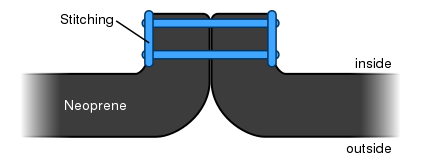

Overlock

This method is the simplest way of stitching, and the least effective at keeping water out. It is not used on high-end wetsuits, and would only be found on summer wetsuit or cheaper wetsuits. The two edges of the panels are rolled together and then stitched to hold them together. This method drastically reduces the flexibility of the seam. It also leaves a bulge on the inside of the wetsuit, which can be uncomfortable and result in chafing - ouch!

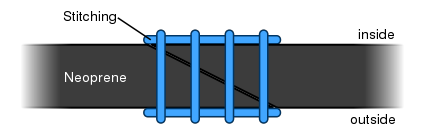

Flatlock

Flatlock stitching involves laying one panel edge over the other, then stitching though the neoprene. The resulting seam is flexible and strong. The drawback to a flatlocked seam is that the process involved creates many holes, and is prone to high water penetration. This makes it more suited to summer or warmer water surfing.

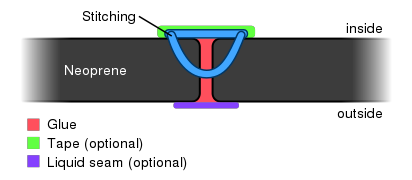

Blindstitch

The edges of the panels are placed end on end and glued together. They are then stitched on the inside, but the stitching does not go all the way through to the outside of the panels. Result: watertight, flexible seams. This is the ideal seam for cold water temperatures, and is the one found on higher quality, more expensive wetsuits. If you are a cold water surfer, do yourself a favour and pay extra for blindstitching.

Double blindstitching can be used on thicker wetsuits, where a seam is blindstitched on one side, the again on the reverse side.

Sealing Seams

Water seepage will reduce the effectiveness of the suit. Fortunately there are a number of ways to increase the warmth of a wetsuit, (without constantly peeing in it) and to increase the strength of a wetsuit's seams.

- Glued Seams: The panels are glued together prior to stitching, increasing the strength of the seam and creating a waterproof seal

- Spot Taped Seams: Tape is glued to the inside of the seam in critical areas to add additional strength where needed

- Fully Taped Seams: Tape is glued to the inside of every seam. Neoprene tape can be used to ensure there is no loss in flexibility

- Liquid Taped: The ultimate seam seal. A special liquid rubber is applied to the inside seam which makes it 100% waterproof.